Equipment Management System (EMS)

Systematic oversight and maintenance of physical laboratory assets, ensuring efficient operation, longevity, and optimal utilization throughout their lifecycle

Labii's Equipment Management System (EMS) provides comprehensive oversight of laboratory instruments, machinery, and physical assets throughout their entire lifecycle. From initial acquisition and installation through daily usage, preventive maintenance, calibration, and eventual retirement, EMS ensures that your laboratory equipment operates efficiently, remains compliant with regulatory requirements, and delivers maximum return on investment.

The system centralizes equipment tracking, usage scheduling, maintenance management, and performance monitoring in a single integrated platform. With real-time availability calendars, automated maintenance reminders, complete audit trails, and seamless integration with electronic lab notebooks, EMS eliminates the inefficiencies of spreadsheet-based equipment management while ensuring regulatory compliance and data integrity.

Whether you're managing analytical instruments in a quality control laboratory, shared research equipment in an academic core facility, or production equipment in a pharmaceutical manufacturing plant, the Equipment Management System (EMS) application provides the tools and flexibility needed to optimize equipment utilization and maintain comprehensive asset documentation.

Use Cases

Equipment Lifecycle Management

Track equipment from procurement through installation, operation, and retirement

Maintain comprehensive equipment specifications, documentation, and certifications

Monitor equipment performance metrics and utilization statistics

Manage warranty information and service contracts

Plan equipment replacement and capital expenditure budgets

Document equipment decommissioning and disposal procedures

Preventive Maintenance and Calibration

Schedule recurring preventive maintenance activities based on time or usage

Track calibration schedules and certificates for analytical instruments

Automate maintenance reminders and notifications

Document maintenance activities with complete audit trails

Manage service contracts and vendor relationships

Generate compliance reports for regulatory inspections (FDA, ISO, GMP, CLIA)

Shared Equipment Scheduling

Reserve equipment to prevent scheduling conflicts

Provide real-time visibility into equipment availability

Manage equipment access permissions and user training requirements

Optimize equipment utilization across multiple teams and projects

Handle priority booking and approval workflows

Support cost recovery and chargeback for shared facility equipment

Usage Documentation and Traceability

Automatically link equipment usage to experiments and sample testing

Maintain complete audit trails of who used equipment, when, and for what purpose

Track equipment performance and associate with experimental outcomes

Support data integrity requirements for regulated laboratories

Enable root cause analysis when equipment issues impact results

Generate equipment usage reports for grant reporting and compliance

Compliance and Quality Assurance

Maintain equipment qualification records (IQ, OQ, PQ)

Track change control for equipment modifications

Document corrective and preventive actions (CAPA)

Support audit readiness with complete equipment documentation

Ensure equipment used for testing is properly calibrated and maintained

Generate regulatory reports for FDA, ISO 17025, CAP, CLIA compliance

Multi-Site Equipment Management

Centralized visibility of equipment across multiple laboratory locations

Standardize equipment management procedures across the organization

Transfer equipment between sites with complete documentation

Consolidated reporting for enterprise equipment portfolio

Manage shared equipment between departments or facilities

Track equipment costs and utilization by site or department

Getting Started

Navigate to the Equipment Management System (EMS) application from the Labii applications menu or dashboard

Configure your equipment management infrastructure:

Equipment categories: Define types of equipment in your laboratory (analytical instruments, processing equipment, support equipment)

Storage locations: Set up buildings, rooms, and specific equipment locations

Maintenance types: Configure preventive maintenance, calibration, repair, and validation categories

User permissions: Establish who can add equipment, schedule usage, and record maintenance

Set up vendor relationships:

Register equipment vendors and service providers in the Vendors (fn_vendor) table

Record vendor contact information and service contract details

Document preferred vendors for specific equipment types

Track vendor performance and response times

Define equipment management workflows:

Booking rules: Configure advance booking periods, maximum reservation duration, approval requirements

Maintenance schedules: Establish standard maintenance intervals for equipment types

Usage documentation: Determine required information for equipment usage records

Alert thresholds: Set up notifications for maintenance due dates and equipment issues

Import existing equipment inventory (optional):

Prepare equipment data in CSV format with required fields

Use bulk import feature to register existing equipment

Verify imported data and add any missing information

Assign equipment to storage locations and responsible personnel

Begin equipment management activities:

Register new equipment as it arrives

Schedule equipment usage to prevent conflicts

Record maintenance and calibration activities

Link equipment usage to experiments and testing

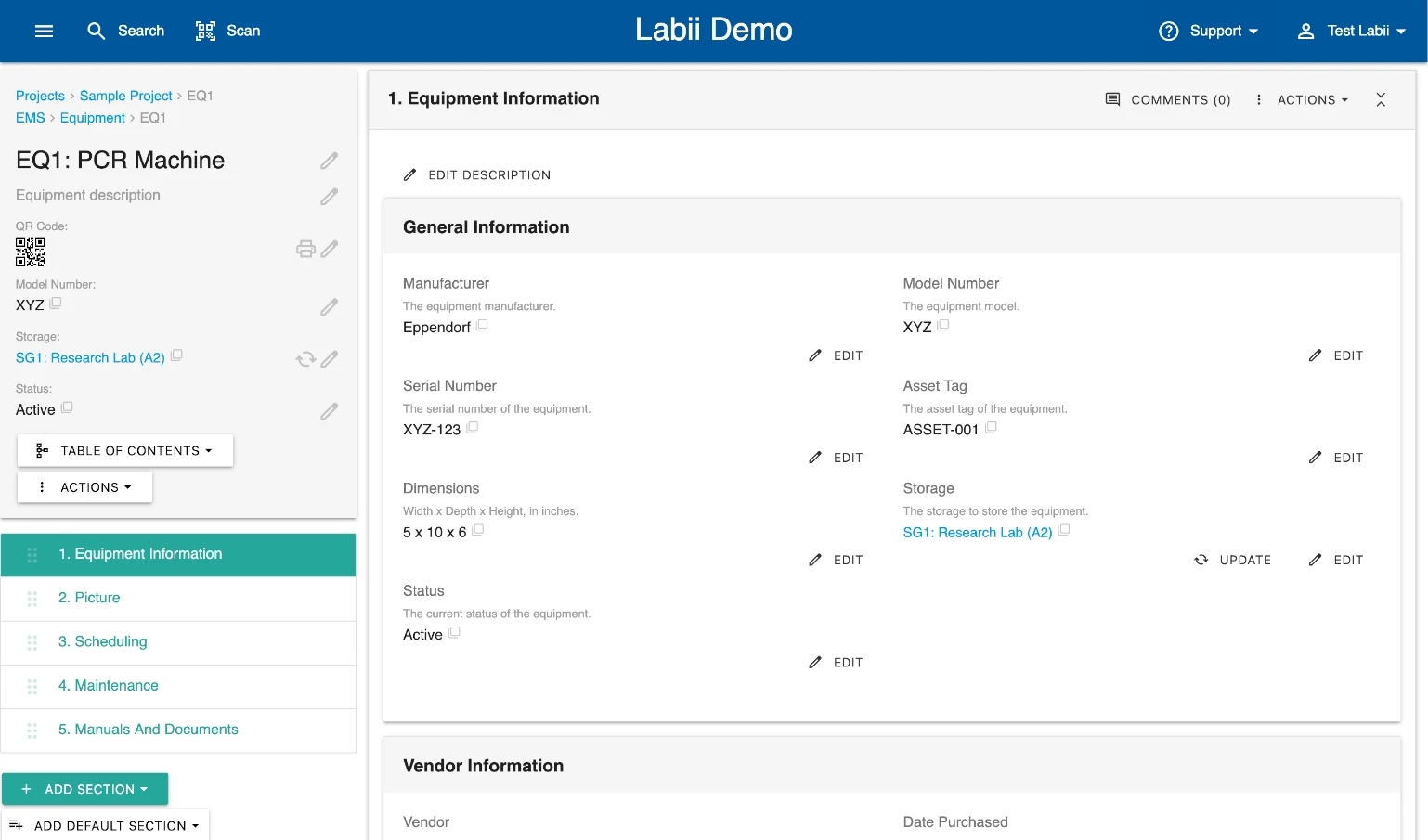

Registering Equipment

Create comprehensive equipment records to track assets throughout their lifecycle.

Navigate to the Equipment table and click + Add to create a new equipment record

Enter equipment identification information:

Equipment name: Descriptive name for easy identification

Equipment ID: Unique identifier (can be auto-generated or manual based on your numbering scheme)

Equipment type: Category (analytical instrument, processing equipment, support equipment, computer system)

Manufacturer: Equipment manufacturer name

Model: Model number or name

Serial number: Manufacturer's serial number

Add procurement and ownership details:

Vendor: Select from registered vendors in fn_vendor table

Purchase order: PO number for tracking

Acquisition date: Date equipment was purchased or received

Purchase cost: Initial capital cost

Funding source: Grant, department budget, or funding source

Asset tag: Organization's asset tracking number

Specify equipment location and assignment:

Location: Building, room, specific position (link to core_storage)

Department: Owning department or unit

Responsible person: Equipment manager or primary contact

Backup contact: Secondary responsible person

Physical location details: Specific placement information (e.g., "left bench, near fume hood")

Configure equipment specifications:

Technical specifications: Performance parameters, capacity, capabilities

Operating conditions: Temperature range, humidity requirements, power requirements

Software version: For instruments with software components

Accessories: List of standard accessories and components

Capacity: Throughput or processing capacity

Set up equipment status and availability:

Operational status: Active, inactive, under repair, decommissioned

Availability: Available for use, reserved, restricted access, training required

Condition: New, good, fair, needs repair

Usage restrictions: Any limitations on use or access

Upload equipment documentation:

User manuals: Operation and instruction manuals

Service manuals: Technical service documentation

Standard operating procedures (SOPs): Internal procedures for equipment use

Calibration certificates: Initial calibration documentation

Installation qualification (IQ): Qualification documentation

Warranty documents: Warranty terms and service contracts

Safety information: Safety data sheets, hazard information

Configure maintenance and calibration schedules:

Set up recurring preventive maintenance schedule

Establish calibration frequency and requirements

Assign maintenance responsibility

Set alert thresholds for upcoming maintenance

Define access and training requirements:

Specify user training requirements

List certified users authorized to operate equipment

Document safety training prerequisites

Set booking permissions and approval requirements

Save the equipment record and print equipment labels or QR codes for physical identification

Use consistent naming conventions and equipment IDs to facilitate searching and reporting. Consider including equipment category and location codes in your ID scheme (e.g., "HPLC-LAB3-001").

Managing Equipment Maintenance

Track preventive maintenance, calibrations, repairs, and service activities to ensure equipment operates reliably and remains compliant.

Recording Completed Maintenance

Navigate to the specific equipment record and locate the Maintenance section, or access the Equipment Maintenance (equipment_maintenance) table directly

Click + Add Maintenance to create a new maintenance record

Select maintenance type:

Preventive maintenance: Scheduled routine maintenance

Corrective maintenance: Repairs to address issues

Calibration: Instrument calibration and adjustment

Qualification/Validation: IQ, OQ, PQ activities

Inspection: Routine inspection or safety check

Cleaning: Routine cleaning or decontamination

Enter maintenance details:

Maintenance date: When maintenance was performed

Performed by: Technician or service personnel

Service provider: Internal staff or external vendor

Duration: Time required for maintenance

Maintenance procedure: Reference to SOP or work instructions

Document maintenance activities:

Work performed: Detailed description of maintenance activities

Parts replaced: List of components or consumables replaced

Consumables used: Supplies consumed during maintenance

Issues found: Any problems discovered during maintenance

Corrective actions: Steps taken to address issues

Recommendations: Suggestions for future maintenance or improvements

Record maintenance costs:

Labor cost: Personnel time or service fees

Parts cost: Cost of replacement components

Travel expenses: If applicable for external service

Total cost: Sum of all maintenance expenses

Billing: Purchase order or invoice reference

Upload maintenance documentation:

Service reports: Technician reports and work summaries

Calibration certificates: Certificates from calibration activities

Test results: Performance verification data

Photos: Before/after photos of maintenance work

Invoices: Service invoices and receipts

Update equipment status:

Set completion status (completed, partially completed, pending approval)

Update equipment operational status if affected

Note any out-of-service period

Document equipment return to service

Set next maintenance due date:

Calculate based on maintenance interval

System can auto-calculate next due date

Adjust for any changes in maintenance schedule

Set reminders for upcoming maintenance

Save the maintenance record and notify relevant personnel of completion and any issues found

Scheduling Future Maintenance

From the equipment record's Maintenance section or the Equipment Maintenance table, click + Add Maintenance and select Schedule Future Maintenance

Define the maintenance schedule:

Scheduled date: Future date for maintenance

Maintenance type: Type of maintenance to perform

Frequency: Recurring schedule if applicable:

Daily, weekly, monthly, quarterly, semi-annually, annually

Custom intervals (every X days, months, or years)

Usage-based (after X hours of operation or Y cycles)

End date: For recurring maintenance, when schedule should end (optional)

Assign maintenance responsibility:

Responsible person: Primary person responsible for ensuring maintenance occurs

Backup contact: Alternate person if primary unavailable

Service provider: External vendor if maintenance performed by third party

Approval required: Whether maintenance needs management approval

Set priority and requirements:

Priority level: Critical, high, medium, low

Estimated duration: Expected time required

Special requirements: Parts needed, equipment shutdown required, safety precautions

Prerequisites: Conditions that must be met before maintenance

Configure notifications:

Advance notice: When to send reminders (e.g., 30, 14, 7, 1 days before)

Recipients: Who should receive maintenance reminders

Escalation: Alerts for overdue maintenance

Notification method: Email, in-app, SMS

Add maintenance instructions:

Link to standard operating procedures

Reference specific work instructions

Note special considerations or precautions

Include vendor service manual references

Save the scheduled maintenance record - system will track and send reminders according to configuration

Usage-based maintenance scheduling is particularly effective for high-use equipment. Configure equipment usage tracking to automatically trigger maintenance when usage thresholds are reached.

Maintenance Compliance and Reporting

Access the Maintenance Dashboard to view overall maintenance status across all equipment

Monitor key maintenance metrics:

Upcoming maintenance: All scheduled maintenance in the next 30 days

Overdue maintenance: Past-due maintenance activities requiring attention

Maintenance completion rate: Percentage of scheduled maintenance completed on time

Equipment downtime: Time equipment is unavailable due to maintenance

Maintenance costs: Total and average maintenance costs by equipment

Generate maintenance compliance reports:

Calibration status report: All equipment with calibration due dates

Maintenance history: Complete maintenance records for specific timeframe

Equipment uptime: Availability and downtime statistics

Cost analysis: Maintenance costs by equipment, department, or time period

Vendor performance: Service provider response times and quality metrics

Review equipment performance trends:

Identify equipment with frequent maintenance issues

Analyze maintenance costs vs. equipment value

Detect patterns requiring preventive actions

Support decisions about equipment replacement

Prepare for regulatory audits:

Generate complete maintenance audit trail

Compile calibration certificates and schedules

Document preventive maintenance compliance

Demonstrate equipment qualification status

Scheduling Equipment Usage

Reserve equipment to prevent conflicts and optimize utilization across laboratory teams.

Navigate to the specific equipment record and access the Scheduling section, or open the Equipment Usage (equipment_usage) table

View equipment availability:

Check the calendar interface showing current reservations

Switch between day, week, or month views

Identify available time slots

View existing reservations and who booked them

Create a new equipment reservation:

Click on an available time slot in the calendar

Or click + Add Usage to create a reservation manually

Select start date and time

Select end date and time (or specify duration)

Enter reservation details:

Purpose: Reason for equipment use (experiment, sample analysis, training, maintenance)

Project: Link to research project or work order

Experiment: Link to specific experiment record in ELN (if applicable)

Description: Brief description of planned work

Expected outputs: What will be produced or measured

Specify users and participants:

Primary user: Person responsible for equipment use

Additional users: Other personnel who will operate equipment

Training verification: Confirm users are trained and authorized

Supervision required: Note if supervision is needed

Configure reservation settings:

Priority level: Normal, high priority, emergency

Buffer time: Add setup time before and cleanup time after main reservation

Notification preferences: Alert options for upcoming reservation

Cancellation policy: Cancellation deadline and procedure

Set up recurring reservations (if applicable):

Enable recurring schedule

Define frequency (daily, weekly, monthly, custom)

Set number of occurrences or end date

System checks availability for all instances

Handle booking conflicts:

System alerts if requested time conflicts with existing reservation

View conflict details and alternative time slots

Contact existing reservation holder if necessary

Request priority override if urgent (subject to approval)

Submit reservation for approval (if required):

Some equipment or time slots may require manager approval

System routes reservation to appropriate approver

Track approval status

Receive notification when approved or declined

Receive confirmation:

Reservation confirmed and added to calendar

Automatic calendar invites sent to participants

Email confirmation with reservation details

Add to personal calendar or Outlook/Google Calendar sync

Recording Actual Equipment Usage

At the time of equipment use, access the reservation from the equipment calendar or your personal reservations list

Check in to start using equipment:

Click Start Usage or Check In

System records actual start time

Equipment status changes to "In Use"

Timer begins tracking usage duration

Record usage information during or after use:

Actual duration: System tracks or manually enter

Samples processed: Number of samples or runs completed

Settings used: Instrument parameters or configurations

Results quality: Pass/fail or quality assessment

Issues encountered: Any problems or malfunctions

Consumables used: Materials consumed during use

Link usage to experimental data:

Attach result files or instrument output

Link to experiment records in ELN

Connect to sample records for traceability

Reference protocols or SOPs followed

Check out when finished:

Click End Usage or Check Out

Verify equipment left in proper state

Confirm cleaning and shutdown procedures completed

Note any issues requiring attention

System records actual end time

Complete usage documentation:

Add post-use notes or observations

Document any equipment performance issues

Recommend maintenance if needed

Save usage record with complete audit trail

Linking equipment usage directly to experiment records in your ELN creates automatic traceability and supports data integrity requirements for regulated laboratories.

Managing Equipment Access and Permissions

Access equipment settings to configure booking rules and access controls

Define user access levels:

Authorized users: List of trained personnel who can use equipment

Booking permissions: Who can make reservations (all users, trained users, managers only)

Administrator: Personnel who can modify equipment settings and schedules

Training required: Specify training prerequisites for equipment use

Configure booking restrictions:

Maximum booking duration: Limit on single reservation length

Advance booking period: How far ahead reservations can be made

Minimum booking notice: Required notice before reservation time

Maximum concurrent bookings: Limit on number of future reservations per user

Set up approval workflows:

Require approval: Enable manager approval for bookings

Auto-approval rules: Conditions for automatic approval

Approval timeout: Deadline for approval responses

Escalation: Who to notify if approval not received

Establish priority rules:

High-priority users: Users who can book with higher priority

Reserved time blocks: Time slots restricted to specific projects or users

Emergency override: Who can override existing reservations in emergencies

Conflict resolution: Procedures for handling booking conflicts

Configure cancellation policies:

Cancellation deadline: How far in advance cancellations must be made

Late cancellation penalties: Consequences for late cancellations or no-shows

No-show tracking: Monitor and address users who don't use reserved time

Automatic release: Free up slots if user doesn't check in

Equipment Performance Monitoring

Track equipment utilization, performance metrics, and costs to optimize laboratory operations.

Access the Equipment Analytics Dashboard from the EMS main menu

Review utilization metrics:

Total usage hours: Equipment operating time over selected period

Utilization rate: Percentage of available time that equipment is in use

Booking efficiency: Ratio of actual usage to reserved time

Peak usage periods: Times of highest demand for equipment

Idle time: Periods when equipment is available but unused

Analyze user statistics:

Active users: Number of different users operating equipment

Usage by user: Breakdown of equipment time by individual users

Usage by department: Equipment time allocated to different teams

Usage by project: Equipment time charged to research projects

No-show rate: Frequency of missed reservations by user

Monitor equipment performance:

Uptime: Percentage of time equipment is operational

Downtime: Time equipment is unavailable due to maintenance or issues

Mean time between failures (MTBF): Average operational time between breakdowns

Mean time to repair (MTTR): Average time to restore equipment to service

Performance trends: Equipment efficiency or output over time

Track maintenance and costs:

Maintenance frequency: Number of maintenance events in period

Maintenance costs: Total and average costs for upkeep

Cost per use: Total ownership cost divided by usage hours

Return on investment (ROI): Value generated relative to equipment cost

Warranty status: Active warranties and coverage

Generate performance reports:

Equipment utilization summary

User activity and allocation reports

Cost analysis and budgeting reports

Compliance and calibration status reports

Equipment comparison reports

Use insights for optimization:

Identify underutilized equipment for reallocation

Detect scheduling bottlenecks and add capacity

Optimize maintenance schedules based on usage patterns

Support equipment replacement decisions

Plan capital equipment investments

Managing Equipment Storage Locations

Organize and track physical locations where equipment is installed and stored.

Navigate to the Storage (core_storage) table to manage equipment locations

Create hierarchical location structure for equipment:

Buildings/Sites: Top-level facilities

Floors: Building levels if applicable

Rooms/Labs: Specific laboratory rooms

Areas: Zones within rooms (e.g., "Instrument Room", "Sample Prep Area")

Positions: Specific locations (e.g., "Left bench", "Fume hood 3")

Define location properties:

Location code: Unique identifier (e.g., "BLDG1-2F-LAB205-INST3")

Location type: Equipment location, storage room, core facility

Capacity: Number of equipment items that can be housed

Environmental conditions: Temperature, humidity, ventilation

Utilities available: Electrical power, gas lines, data connections

Access restrictions: Security requirements, key codes, authorized personnel

Assign equipment to locations:

Link equipment records to specific storage locations

Track equipment movements between locations

Document installation date and configuration

Record environmental monitoring data

Note any special installation requirements

Track location capacity and utilization:

View all equipment assigned to each location

Monitor space utilization

Plan for new equipment installations

Identify opportunities for space optimization

Generate location-based reports:

Equipment inventory by location

Space utilization analysis

Equipment value by location

Maintenance schedules by location

Managing Equipment Vendors

Maintain relationships with equipment manufacturers, service providers, and suppliers.

Navigate to the Vendors (fn_vendor) table to manage vendor relationships

Create vendor records for equipment suppliers:

Vendor name: Company name

Vendor type: Manufacturer, distributor, service provider, calibration lab

Contact information: Phone, email, website, address

Account number: Your account identifier with vendor

Primary contact: Sales rep or service coordinator name

Document service agreements:

Service contract: Active service contracts and terms

Contract period: Start and end dates

Coverage: What services are included (preventive maintenance, repairs, calibration)

Response time: Guaranteed service response times

Cost: Annual contract cost or per-service pricing

Link vendors to equipment:

Associate vendor with equipment they manufactured or service

Track warranty information and expiration dates

Note preferred vendors for specific equipment types

Document vendor performance and service quality

Manage vendor performance:

Track service response times

Document service quality and issues

Monitor costs and billing accuracy

Review and update vendor ratings

Consider alternatives if performance issues occur

Advanced Features

Automated Maintenance Scheduling

Configure intelligent scheduling that adapts to actual equipment usage patterns.

Usage-based maintenance scheduling extends equipment life and reduces unnecessary maintenance by servicing equipment based on actual wear rather than arbitrary time intervals.

Enable usage tracking for equipment:

Configure usage meters (hours, cycles, samples processed)

Integrate with equipment software for automatic usage capture

Or manually record usage hours after each use

Define usage-based maintenance triggers:

Set maintenance interval in usage units (e.g., every 500 hours of operation)

Combine with time-based maximums (e.g., every 500 hours or 12 months, whichever comes first)

Configure multiple trigger points for different maintenance types

System automatically:

Tracks cumulative usage since last maintenance

Calculates predicted maintenance due dates based on usage trends

Generates maintenance alerts when thresholds are reached

Adjusts schedules as usage patterns change

Review and optimize maintenance schedules:

Analyze relationship between usage and maintenance needs

Adjust trigger points based on equipment performance data

Identify equipment requiring more or less frequent maintenance

Reduce maintenance costs while maintaining reliability

Equipment Qualification and Validation

Manage installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ) for regulated equipment.

Create qualification records for new equipment:

Link to equipment record

Specify qualification type (IQ, OQ, PQ, requalification)

Assign qualification protocol and responsible personnel

Set completion deadline

Document qualification activities:

Record qualification test procedures performed

Attach test results and acceptance criteria

Document deviations and resolutions

Obtain approval signatures from quality assurance

Track qualification status:

Initial qualification completion dates

Requalification schedule and frequency

Current qualification status (qualified, expired, pending)

Alert for expiring qualifications

Generate qualification documentation:

Complete qualification reports for regulatory inspections

Equipment qualification certificates

Qualification history and audit trails

Change control documentation for equipment modifications

Integration with Electronic Lab Notebook

Seamlessly link equipment usage to experimental records for complete traceability.

Enable ELN-EMS integration in application settings

Add equipment widgets to experiment templates:

Insert equipment selection widget in experiment records

Configure to show only equipment relevant to experiment type

Enable automatic usage logging when equipment is selected

Select equipment in experiments:

Search and select required equipment from available inventory

System checks equipment availability and reserves time slot

Verifies equipment calibration status and suitability

Links equipment record to experiment automatically

Automatic data capture:

Equipment usage automatically recorded with experiment

Usage duration linked to experiment timeline

Equipment settings and configurations documented

Creates traceability between equipment and results

Impact analysis and troubleshooting:

View all experiments using specific equipment

Investigate equipment-related issues across experiments

Support root cause analysis if equipment malfunction affects results

Enable scientific reproducibility with complete equipment documentation

Mobile Equipment Management

Use mobile devices for equipment tracking and management on the laboratory floor.

Access Labii EMS from mobile browser or app on smartphone or tablet

Scan equipment barcodes or QR codes:

Use device camera to scan equipment labels

Instantly access equipment record and status

View availability and make reservations

Record maintenance or usage on the spot

Mobile check-in/check-out:

Start equipment usage sessions from mobile device

Record usage notes and parameters

Capture photos of equipment setup or issues

End session and document results

Maintenance recording in the field:

Service technicians record maintenance as it's performed

Upload photos and documents from mobile device

Capture signatures for maintenance approval

Update equipment status in real-time

Location-based features:

View equipment near current location

Navigate to equipment locations

Track equipment movements between locations

Verify equipment is in correct location during audits

Equipment Cost Tracking and Chargeback

Allocate equipment costs to projects, departments, or external clients for accurate budgeting and billing.

Configure cost tracking settings for equipment:

Set hourly usage rate or cost per sample

Define maintenance and service cost allocation rules

Establish billing cycles and invoicing procedures

Configure cost centers and charging accounts

Automatic cost capture:

System calculates costs based on actual usage duration

Allocates costs to projects or grants linked to usage

Tracks maintenance costs by equipment

Accumulates total cost of ownership

Generate cost reports:

Usage costs by project or principal investigator

Department-level equipment expense reports

Client billing reports for core facilities

Budget tracking and forecasting reports

Equipment ROI analysis

Export for billing and accounting:

Generate invoices for external users or clients

Export to accounting or ERP systems

Reconcile equipment revenue with budgets

Support grant reporting requirements

Regulatory Compliance Features

Maintain comprehensive documentation for FDA, ISO, GMP, CLIA, and other regulatory requirements.

Regulatory compliance features should be configured according to your specific requirements (FDA 21 CFR Part 11, ISO 17025, CAP, CLIA, etc.). Consult with your quality assurance team to ensure proper configuration.

Enable comprehensive audit trail:

Record all equipment transactions with timestamps

Capture user identity for every action

Track all modifications to equipment records

Maintain tamper-proof audit logs

Include electronic signature for critical actions

Implement equipment change control:

Document all equipment modifications or moves

Require approval for changes that impact validation status

Track change history and justifications

Link changes to requalification activities

Maintain complete change history

Manage calibration and maintenance compliance:

Track calibration schedules and certificates

Alert for expired calibrations

Prevent use of equipment with expired calibration

Document calibration traceability to standards

Maintain complete calibration history

Generate compliance reports:

Equipment qualification status reports

Calibration compliance reports

Maintenance compliance and audit trails

Equipment usage logs with complete traceability

System validation documentation

Audit-ready documentation packages

Support regulatory inspections:

Provide read-only inspector access

Generate inspection-ready reports

Demonstrate data integrity controls

Show complete equipment documentation

Document corrective actions for any deviations

Troubleshooting

Issue: Cannot Reserve Equipment - Shows as Unavailable

Symptoms: Equipment appears unavailable for booking even when calendar shows no conflicts

Solution:

Check equipment operational status - navigate to equipment record and verify status is "Active" or "Available". Equipment marked as "Under Maintenance" or "Out of Service" cannot be reserved

Verify your user permissions - confirm you have booking permissions for this equipment. Check with equipment manager or administrator if access is restricted

Review equipment access restrictions:

Some equipment may require training certification before booking

Check if equipment is restricted to specific departments or projects

Verify you meet any prerequisite requirements

Check for maintenance blackout periods - equipment may have scheduled maintenance blocking reservations during that timeframe

Review booking rules:

Equipment may have maximum advance booking period (e.g., can only book 30 days ahead)

Some equipment requires minimum notice period (e.g., must book at least 24 hours in advance)

Check maximum booking duration limits

Contact equipment manager if equipment should be available but remains unbookable

Issue: Maintenance Reminder Notifications Not Arriving

Symptoms: Scheduled maintenance due dates pass without receiving advance notifications

Solution:

Verify notification settings:

Navigate to User Settings > Notifications

Confirm maintenance reminders are enabled

Check email address is correct and current

Check equipment maintenance configuration:

Open equipment record and review maintenance schedule

Verify maintenance has future scheduled date

Confirm notification recipients are properly assigned

Check advance notice period is configured (e.g., 30, 14, 7 days before)

Test email delivery:

Check spam/junk folders for Labii notifications

Verify email server is not blocking Labii emails

Test notification system by triggering a test alert

Confirm email notifications work for other Labii features

Review maintenance record status:

Ensure maintenance is marked as "Scheduled" not "Completed"

Verify scheduled date is in the future

Check if maintenance was already marked completed, canceling future alerts

Contact Labii support if notifications still not working, providing:

Equipment ID and name

Screenshot of maintenance schedule

Screenshot of notification settings

Example of missed notification

Issue: Equipment Usage Record Not Linking to Experiment

Symptoms: Equipment used in experiment but usage doesn't appear in equipment usage history or experiment equipment section

Solution:

Verify you used the equipment widget in the experiment:

Equipment must be added through the equipment selection widget in ELN

Manual notes about equipment use don't create automatic links

Check the experiment's Equipment section for proper equipment entries

Check equipment usage record was created:

Navigate to Equipment Usage table

Search for usage records from the date in question

Verify usage record exists and has correct experiment link

Confirm ELN-EMS integration is enabled:

Check application settings for integration status

Verify your user role has permission to link equipment to experiments

Confirm equipment record allows ELN integration

Review experiment status:

Draft experiments may not show equipment links until published

Check experiment is in correct project and accessible

Verify no permission restrictions on experiment

Manually link equipment usage if needed:

Create equipment usage record

Add link to experiment in usage record

Or add equipment to experiment's equipment section

Verify bidirectional link is established

Issue: Equipment Calibration Status Shows Expired But Calibration Was Recently Completed

Symptoms: Equipment calibration status shows expired despite recent calibration maintenance

Solution:

Verify calibration maintenance record was saved correctly:

Navigate to equipment's Maintenance section

Locate the recent calibration record

Confirm record shows completion date and status "Completed"

Check if "Next Calibration Due Date" was set:

Open the calibration maintenance record

Verify "Next Due Date" field is populated with future date

System uses this date to calculate calibration status

Update calibration schedule:

If next due date missing, edit calibration record

Calculate next due date based on calibration interval

Enter next due date and save

System should update calibration status

Verify calibration certificate was uploaded:

Some configurations require certificate upload to validate calibration

Upload calibration certificate to maintenance record

Check if certificate triggers status update

Refresh equipment record:

Close and reopen equipment record

Or refresh browser page

Status should update to show current calibration status

Check calibration interval settings:

Review equipment's default calibration interval

Verify interval matches your requirements

Adjust if needed for future calibrations

Always set the "Next Due Date" when recording calibration maintenance to ensure calibration status remains accurate and alerts trigger at appropriate times.

Issue: Cannot Find Equipment in Search Results

Symptoms: Equipment exists but doesn't appear when searching by name or ID

Solution:

Verify equipment name and ID spelling - check for typos, extra spaces, or special characters

Clear search filters:

Remove all active filters

Check status filter - inactive equipment may be hidden

Clear location, category, or other limiting filters

Check equipment status:

Navigate directly to Equipment table and browse

Verify equipment exists and check its status

Archived or decommissioned equipment may not appear in default searches

Review user permissions:

Confirm you have access to equipment's project or team

Some equipment may have restricted visibility

Contact administrator if permission issue suspected

Try different search methods:

Search by manufacturer or model instead of name

Use partial name matching

Search by serial number or asset tag

Use barcode scanner if equipment has barcode label

Check equipment was actually created and saved:

Verify equipment record exists in Equipment table

Confirm save was successful when equipment was registered

Review recent equipment additions with administrator

Issue: Scheduled Maintenance Not Appearing on Calendar

Symptoms: Scheduled maintenance doesn't show up on equipment calendar or maintenance dashboard

Solution:

Verify maintenance was saved as "Scheduled":

Open equipment maintenance record

Check status is "Scheduled" not "Draft" or "Completed"

Confirm scheduled date is set

Check calendar date range:

Ensure calendar view includes the scheduled maintenance date

Expand date range if viewing limited timeframe

Switch to month view to see broader schedule

Review calendar filters:

Check maintenance type filter - may be filtering out this type

Verify user filter includes assigned personnel

Clear all filters and check again

Confirm maintenance is assigned to correct equipment:

Open maintenance record

Verify equipment link is correct

Check maintenance appears in equipment's Maintenance section

Refresh calendar view:

Reload browser page

Switch calendar views (day/week/month)

Log out and log back in

Clear browser cache if persistent

Check calendar permissions:

Verify you have permission to view maintenance calendar

Confirm maintenance assigned to personnel you can view

Contact administrator about calendar access settings

Issue: Equipment Utilization Report Shows Incorrect Data

Symptoms: Equipment utilization reports or dashboards display inaccurate usage statistics

Solution:

Verify report date range:

Check start and end dates for report

Ensure date range matches your intended analysis period

Adjust date range and regenerate report

Review usage records for accuracy:

Navigate to Equipment Usage table

Filter by equipment and date range

Verify usage records match actual equipment use

Check for missing usage records that should have been created

Identify incomplete usage records:

Look for usage records with start time but no end time

Find reservations that were made but equipment not actually used (no check-in)

Check for test or training usage that should be excluded

Verify equipment operational hours:

Check equipment availability schedule (if configured)

Utilization calculated against available hours, not calendar hours

Adjust availability schedule if needed

Review calculation method:

Understand how utilization is calculated (reserved time vs. actual usage time)

Check if report includes or excludes maintenance downtime

Verify whether setup/cleanup buffer time is included

Correct data issues:

Add missing usage records for actual equipment use

Complete incomplete usage records with end times

Remove or mark as canceled any no-show reservations

Regenerate report after corrections

Related Documentation

Inventory Management - Track consumables and supplies used with equipment

Sample Management - Link equipment usage to sample processing and testing

Storage Management - Organize physical equipment locations

Electronic Lab Notebook - Integrate equipment usage into experimental documentation

Laboratory Information Management System - Connect equipment to sample testing workflows

Project Management - Associate equipment with research projects and track costs

Vendors Management - Manage equipment suppliers and service providers

API - Equipment Endpoints - Programmatic access to equipment data

Admin Guide - Teams - Configure user permissions for equipment management

Admin Guide - Workflows - Automate equipment management workflows

User Guide - Barcode Scanning - Implement barcode tracking for equipment

Last updated